Grayson is a shopping aficionado who loves to share information about the best deals and steals he finds. He's always on the lookout for a bargain, and he loves to help others find great deals, too. You can always count on Denise to give you the inside scoop on where to shop and save money.

In the pharmaceutical manufacturing industry, precision and efficiency are paramount. One of the key technologies that facilitate these goals is the PLC. Understanding what PLC means and its role in this sector provides valuable insights into modern manufacturing processes.

Understanding PLC

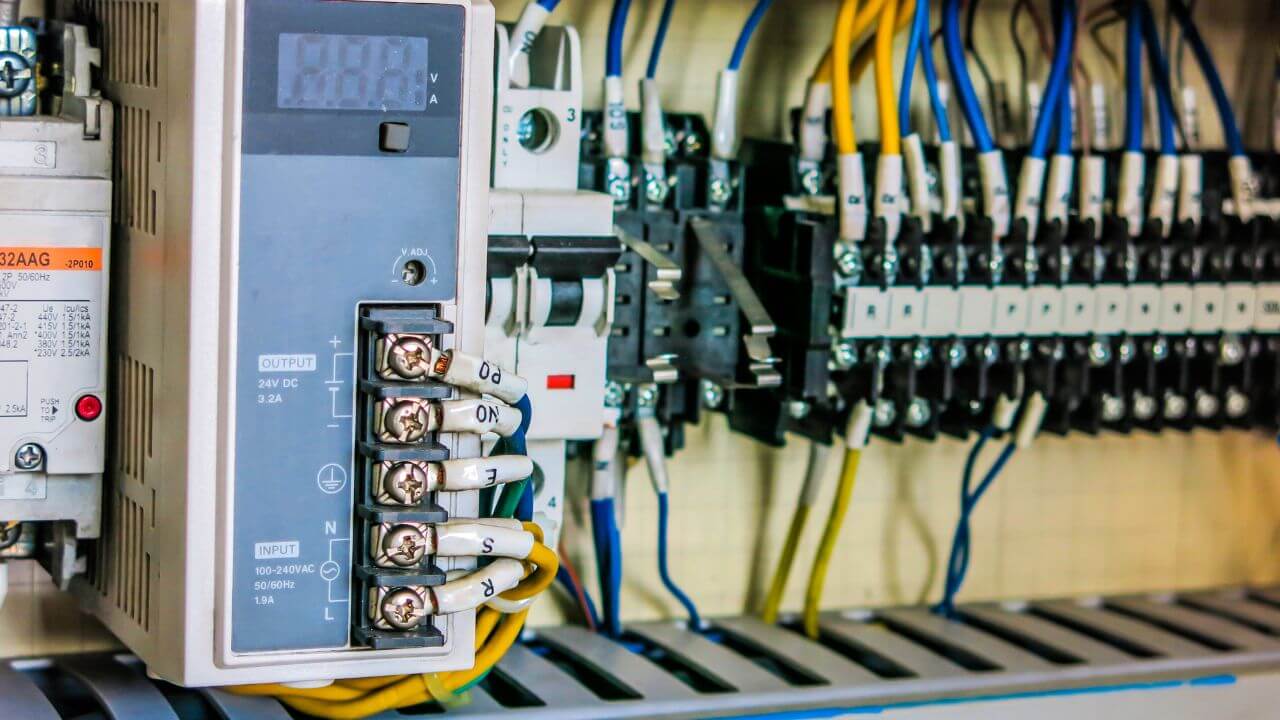

PLC stands for Programmable Logic Controller. It is a specialized computer used to control machinery and processes in industrial settings. In pharmaceutical manufacturing, PLCs automate complex tasks, ensuring that operations run smoothly and efficiently.

The Role of PLC in Manufacturing

PLCs are integral to automating repetitive and precise tasks. They manage production lines, control equipment, and monitor processes. This automation reduces human error and enhances productivity, which is crucial in an industry where accuracy is essential.

Benefits of Using PLCs

PLCs offer numerous advantages in pharmaceutical manufacturing. They provide consistent and reliable control over processes, ensuring that products meet stringent quality standards. Additionally, PLCs are flexible and can be easily programmed to adapt to changing production needs.

How PLCs Work

PLCs function by receiving input signals from sensors and other devices. They process these signals based on pre-set instructions and send output signals to control machinery. This capability allows for precise management of manufacturing operations.

Importance of PLCs in Quality Control

Quality control is a critical component of pharmaceutical manufacturing. PLCs play a vital role in maintaining quality by continuously monitoring processes and ensuring adherence to standards. This monitoring helps identify and address issues before they affect the final product.

Future Trends in PLC Technology

As technology advances, PLCs are becoming more sophisticated. Developments include enhanced connectivity and integration with other systems, making PLCs even more effective in managing complex manufacturing processes.

Challenges in Implementing PLCs

While PLCs offer many benefits, their implementation can be challenging. It requires careful planning and expertise to integrate them effectively into existing systems. Training staff to operate and maintain PLCs is also essential for successful implementation.

Conclusion

Understanding what PLC means in pharmaceutical manufacturing is crucial for industry professionals. PLCs are a vital component of modern manufacturing, offering automation, precision, and efficiency.

As technology continues to evolve, PLCs will play an increasingly significant role in shaping the future of pharmaceutical production. Embracing this technology can lead to improved processes and higher quality products, benefiting both manufacturers and consumers.